#RASTER IMAGE VS VECTOR SOFTWARE#

However, it is important that your laser software supports the SVG format to work with Vector graphics.Furthermore, Vector engraving works best for flat materials like wood, leather, plastic, and metal because the laser moves from point to point.You can adjust the laser power for etching, engraving, and cutting the material.Usually, the overall process of Raster and Vector laser engraving is the same except for the laser power settings.Once the outline is finished, the next step is to fill the outline by tracing different paths of engraving.When you press the print button, the laser moves on the X and Y-axis to draw the design’s outline.Moreover, you must also adjust the laser settings like speed, focus, power, and color before starting the process.When you input the Vector file in the laser software, it processes the image to understand the different paths.However, laser engraving Vector is a bit faster than Raster because the laser moves from point to point instead of line by line. Vector laser engraving is very similar to Raster as the laser movement is bi-directional in this case as well.

#RASTER IMAGE VS VECTOR PROFESSIONAL#

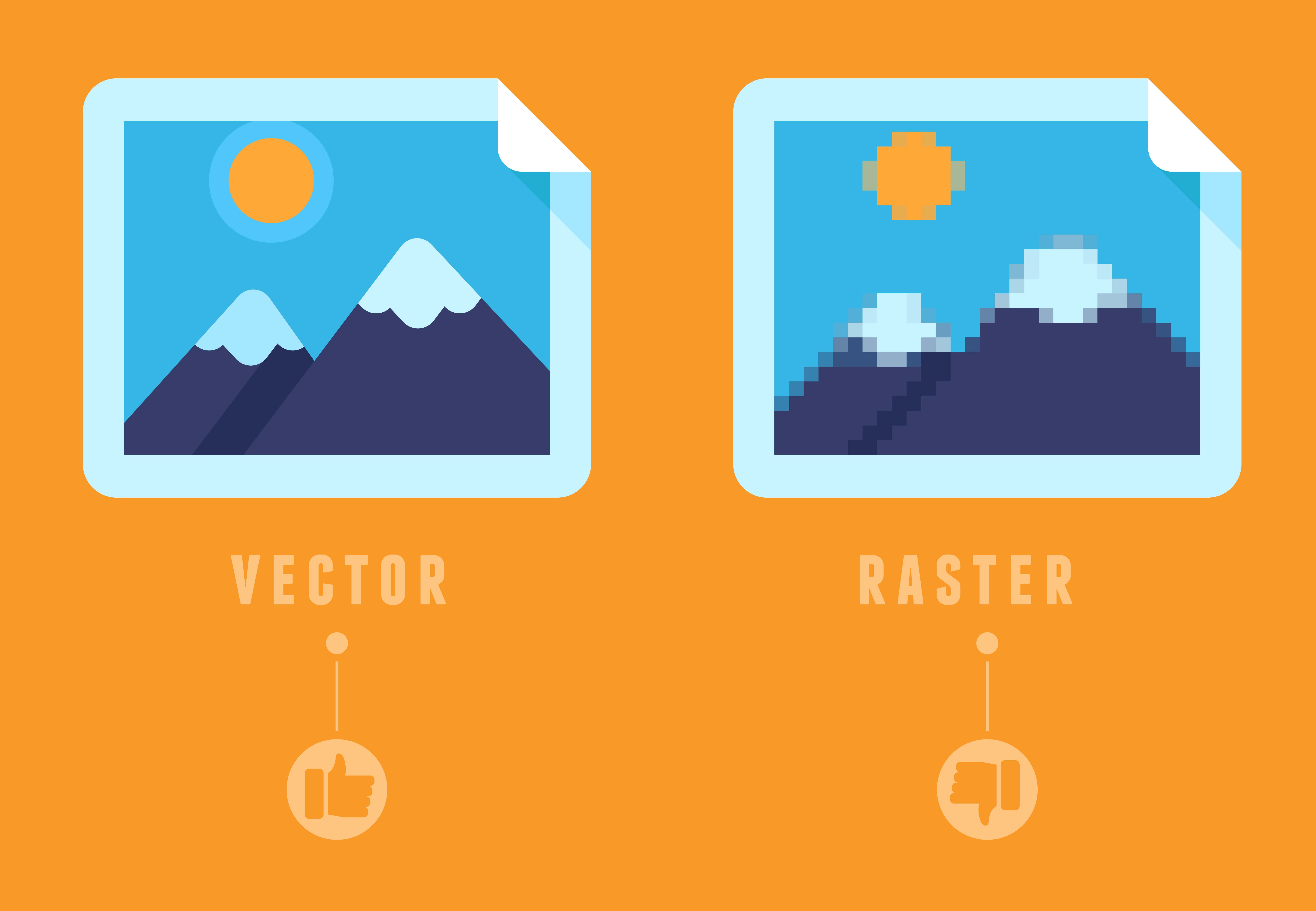

So, it is important that you get a good grip on professional tools like AutoCAD, Illustrator, or CorelDraw to design in Vector format. However, only a few software applications can generate the Vector or Scalable Vector Graphics (SVG). The major benefit of a Vector design is that it doesn’t lose quality or clarity even at maximum zoom. The path is formed by a mathematical formula that determines the color and shape of the path. Unlike Raster images, the Vector images are made from lines and curves, also known as paths.

The raster images are better known as bitmap images. However, the resolution of the image remains constant, and the image will become distorted when you zoom beyond the safe limits. Raster images are made up of millions of small pixels each pixel represents a portion of the image.

0 kommentar(er)

0 kommentar(er)